Ngokuphathelele kwiintlawulo ezikhuphisanayo, sikholelwa ukuba uya kukhangela kude nakude kuyo nayiphi na into enokusoyisa. Sizakuchaza ngokuqiniseka ngokupheleleyo ukuba kwezo ntlawulo zintle singabona basezantsi kwiiNkampani zokuVelisa iSilicon Carbide Ring, i-Corrosion Resistant, itywiniwe, nawuphi na umdla, khumbula ukuziva ukhululekile ngokupheleleyo ukunxibelelana nathi. Sijonge phambili ekwenzeni ubudlelwane obunempumelelo kumashishini amancinci nabathengi abatsha ngaphakathi kokusingqongileyo ngelixa sikummandla wexesha elide.

Ngokuphathelele kwiintlawulo ezikhuphisanayo, sikholelwa ukuba uya kukhangela kude nakude kuyo nayiphi na into enokusoyisa. Siyakuxela ngokuqinisekileyo ukuba ngokugqwesa ngolo hlobo kwiintlawulo ezinjalo sibe sesona siphantsi kakhuluUmsesane wokutywina waseTshayina kunye neSilicon Carbide yokutywina iRing, Yintoni ixabiso elihle? Sinika abathengi ngexabiso lasefektri. Kwisiseko somgangatho olungileyo, ukusebenza kakuhle kufuneka kuthathelwe ingqalelo kwaye kugcinwe iingeniso ezifanelekileyo eziphantsi nezisempilweni. Yintoni ukuhanjiswa okukhawulezayo? Senza ukuhanjiswa ngokweemfuno zabathengi. Nangona ixesha lokuhambisa lixhomekeke kubungakanani bomyalelo kunye nobunzima balo, sisazama ukubonelela ngezisombululo ngexesha. Ngethemba elinyanisekileyo sinokuba nobudlelwane beshishini bexesha elide.

I-siliconized graphite yinto edibeneyo apho i-silicon carbide ifakwe kumphezulu we-graphite substrate. Ineempawu zokuqina okuphezulu, amandla aphezulu omatshini kunye nokumelana nokunxiba kwe-silicon carbide, kunye neempawu zokuzithambisa kunye nokumelana nobushushu bobushushu begraphite. Yimathiriyeli efanelekileyo yokukhuhlana kunye nezixhobo zokutywinwa ngoomatshini, ezifanelekileyo ukutywinwa koomatshini beempompo zamanzi ezahlukeneyo, iimpompo zeoyile, iimpompo zekhemikhali, kunye neebheringi zeempompo eziphambili ezinesantya esiphezulu kunye nomthwalo ophezulu. Ukongeza, i-siliconized graphite inokumelana ne-oxidation elungileyo, ukuxhathisa ukothuka kwe-thermal, i-porosity ephantsi, kunye nokuhanjiswa kombane okuthile, kwaye inokusetyenziswa njengezinto ezinjengeentsimbi zokunyibilikisa iityhubhu kunye neetyhubhu eziyidrafti.

Ukubunjwa kwe-siliconized graphite kufana, umphezulu uhambelana nengaphakathi, kwaye umlinganiselo wokubunjwa kwe-silicon carbide kunye negraphite iyalungiswa. Okukhona uphezulu umxholo we-silicon carbide, kokukhona ubuninzi bezinto eziphathekayo, amandla oxinzelelo aphezulu, kunye nokumelana nokunyuka.

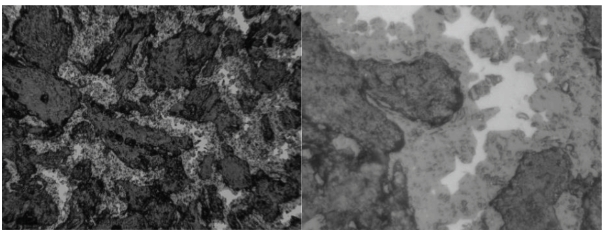

Umfanekiso we-metallographic we-siliconized graphite

(inxalenye emnyama yigraphite, inxalenye engwevu yisilicon carbide, kwaye inxalenye emhlophe yisilicon)

| 硅化石墨主要技术指标 | |

| 类别 Into | ILogo Simahla Akukho mlinganiselo Ipapashwe ngu- Value |

| 密度 Ubuninzi | 2.4-2.9g/cm³ |

| 孔隙率 Porosity | <0.5% |

| 抗压强度 Amandla acinezelayo | > 400MPa |

| 抗折强度 Amandla e-Flexural Amandla e-Flexural | > 120MPa |

| 热导率 I-Thermal conductivity | 120W/mK |

| 热膨胀系数 I-coefficient yokwandiswa kweThermal | 4.5×10-6 |

| 弹性模量Imodyuli yelastiki | 120GPa |

| 冲击强度 Amandla empembelelo | 1.9KJ/m² |

| 水润滑摩擦系数 Ukukhuhlana kwamanzi okuthambisa | 0.005 |

| 干摩擦系数Dry friction coefficient | 0.05 |

| 化学稳定性 Uzinzo lwekhemikhali | 各种盐,有机溶剂,强酸(HF,HCl,H₂SO4,HNO₃) Iityuwa ezahlukeneyo, izinyibilikisi eziphilayo, iiasidi ezinamandla (HF,HCl,H₂SO4,HNO₃) |

| 长期稳定使用温度 Ubushushu bokusetyenziswa kwexesha elide oluzinzileyo | 800℃(氧化气氛), 2300℃(惰性或真空气氛) I-800 ℃ (i-oxidizing atmosphere), 2300 ℃ (inert okanye ivacuum umoya) |

| 电阻率 Ukuxhathisa koMbane | 120×10-6Ωm |

Ngokuphathelele kwiintlawulo ezikhuphisanayo, sikholelwa ukuba uya kukhangela kude nakude kuyo nayiphi na into enokusoyisa. Sizakuchaza ngokuqiniseka ngokupheleleyo ukuba kwezo ntlawulo zintle singabona basezantsi kwiiNkampani zokuVelisa iSilicon Carbide Ring, i-Corrosion Resistant, itywiniwe, nawuphi na umdla, khumbula ukuziva ukhululekile ngokupheleleyo ukunxibelelana nathi. Sijonge phambili ekwenzeni ubudlelwane obunempumelelo kumashishini amancinci nabathengi abatsha ngaphakathi kokusingqongileyo ngelixa sikummandla wexesha elide.

IiNkampani zokuSebenza zeUmsesane wokutywina waseTshayina kunye neSilicon Carbide yokutywina iRing, Yintoni ixabiso elihle? Sinika abathengi ngexabiso lasefektri. Kwisiseko somgangatho olungileyo, ukusebenza kakuhle kufuneka kuthathelwe ingqalelo kwaye kugcinwe iingeniso ezifanelekileyo eziphantsi nezisempilweni. Yintoni ukuhanjiswa okukhawulezayo? Senza ukuhanjiswa ngokweemfuno zabathengi. Nangona ixesha lokuhambisa lixhomekeke kubungakanani bomyalelo kunye nobunzima balo, sisazama ukubonelela ngezisombululo ngexesha. Ngethemba elinyanisekileyo sinokuba nobudlelwane beshishini bexesha elide.

-

OEM China Nxiba Refractory Tube Cerami...

-

China Supplier Silicon Carbide Sic Spray Nozzle

-

IFactory yokuthengisa eshushu Al2O3/Alumina Ceramic Transpor...

-

Imveliso eNtsha yaseTshayina yeSilicon Carbide Radiation Sis...

-

Isixhobo sokuFudumeza seSic esikwiMgangatho oPhezulu, isifudumezi seSic, iS...

-

Izinto eziRefractory ezithengiswa kakhulu-ubushushu obuphezulu...