Inkcazo

I-Silicon carbide igubu lokusila ithatha inkqubo yokubumba i-isostatic, ubuninzi be-3.09g / cm3, ubuninzi be-φ950mm, ubulukhuni beVickers 2550HV.

Ukusetyenziswa kweSilicon Carbide igubu lokusila i-ceramic kwinto yokufudumeza

I-silicon carbide i-ceramic grinding barrel iye yaba yinto ekrwada yezinto ze-cathode ze-lithium ibhetri ngenxa yepropathi yayo ebalulekileyo.I-SiC yokufudumeza into ebalulekileyo yimveliso ebalulekileyo ye-SiC kwaye inethemba elibanzi lemarike.

I-silicon ye-carbide yokugaya i-barrel inzuzo

(1) Amandla aphezulu oomatshini, njengoko kunjalo

Amandla aphezulu omatshini anokuthintela ngokufanelekileyo ukuguqulwa kwezinto eziphathekayo, okubaluleke kakhulu.I-Silicon carbide inamandla omatshini aphezulu kune-corundum.Umzekelo, amandla acinezelayo e-silicon carbide yi-224MPa, ngelixa i-corundum yi-75.7MPa kuphela.Amandla okugoba e-silicon carbide yi-15.5MPa, kwaye eye-corundum yi-8.72MPa.

(2) Ubunzima obuphezulu kunye nokuxhatshazwa kokugqoka

Ubunzima beSilicon carbide buphezulu kakhulu, ngokobulukhuni benotshi ye-Mohs phakathi kwe-9.2 ~ 9.6, okwesibini kuphela kwidayimane kunye ne-boron carbide, iphezulu kune-corundum, ngoko ke ekusileni okuqhelekileyo kunye nokungcangcazela phakathi kwezona zibalaseleyo.Xa kuthelekiswa nezinto zetsimbi zetsimbi, akukhona kuphela ubulukhuni obuphezulu, kodwa nakwimeko engeyiyo yokuthambisa i-friction coefficient incinci, i-friction encinci, uburhabaxa bomphezulu buncinci, ukumelana nokunxiba kulungile.Ukongeza kwizinto zangaphandle zinefuthe elinamandla lokuchasa, phucula umthamo wokuthwala umphezulu.

(3) Ubuninzi obuphantsi

Ubuninzi be-silicon carbide bungaphantsi kuneyentsimbi, ngoko ke izixhobo zikhaphukhaphu.

Inkampani

I-Wei Tai Energy Technology Co., Ltd. (i-Miami Advanced Material Technology Co., Ltd) ngumboneleli ohamba phambili weeseramics ze-semiconductor eziphambili kunye nomvelisi kuphela e-China onokunika ngaxeshanye ukubonelela nge-silicon carbide ceramic ecocekileyo (ingakumbi i-Recrystallized SiC) kunye CVD SiC ukutyabeka.Ukongeza, inkampani yethu izibophelele kumasimi e-ceramic afana ne-alumina, i-aluminium nitride, i-zirconia, kunye ne-silicon nitride, njl.

Iimveliso zethu eziphambili ziquka: i-silicon carbide etching disc, i-silicon carbide boat tow, i-silicon carbide wafer boat (Photovoltaic & Semiconductor), i-silicon carbide furnace tube, i-silicon carbide cantilever paddle, i-silicon carbide chucks, i-silicon carbide beam, kunye ne-CVD SiC coating kunye ne-TaC. ukutyabeka.Iimveliso ezisetyenziswa ikakhulu kwi-semiconductor kunye namashishini e-photovoltaic, njengezixhobo zokukhula kwekristale, i-epitaxy, i-etching, ukupakishwa, ukugquma kunye neziko lokusasaza, njl.

Inkampani yethu inezixhobo ezipheleleyo zokuvelisa ezifana nokubumba, ukuthambisa, ukusetyenzwa, izixhobo zokugquma, njl., ezinokugqiba onke amakhonkco ayimfuneko emveliso yemveliso kwaye ibe nokulawulwa okuphezulu komgangatho wemveliso;Isicwangciso esilungileyo sokuvelisa sinokukhethwa ngokweemfuno zemveliso, okubangela iindleko eziphantsi kunye nokubonelela abathengi ngeemveliso ezikhuphisanayo;Singakwazi ukuguquguquka kunye nokusebenza ngokufanelekileyo kwimveliso esekelwe kwiimfuno zokuhanjiswa kwe-odolo kunye ngokubambisana neenkqubo zolawulo lwe-intanethi, ukubonelela abathengi ngokukhawuleza kunye nexesha lokuhambisa eliqinisekisiweyo.

-

I-Thermal insulation graphite carbon fiber ivakala nzima

-

Isikhephe seSilicon carbide

-

Ukucoceka okuphezulu kweSiC Carrier / Umxhasi

-

Ubushushu obuphezulu bokumelana nesilicon carbide cera...

-

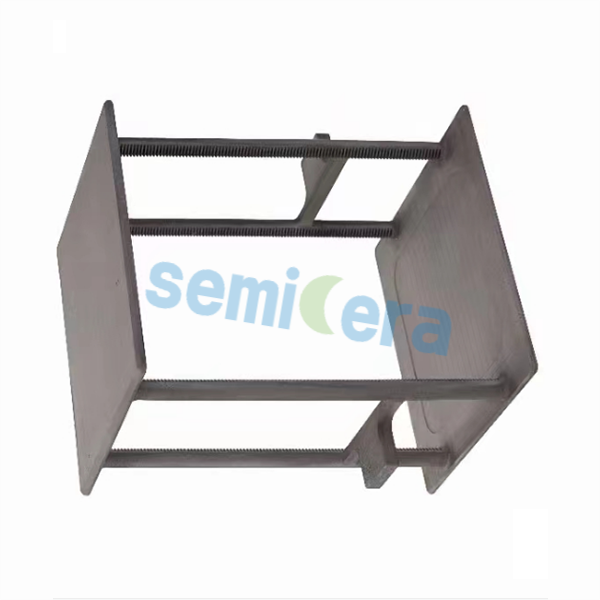

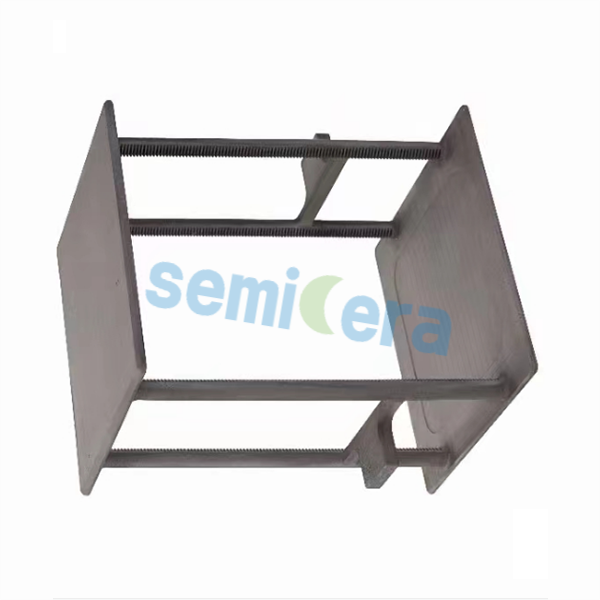

Umsesane weSilicon carbide wokutywina weSilicon carbide press...

-

I-SIC ekhethekileyo yococeko oluphezulu lwegraphite crucible 6-inc...