Uphuhliso lwethu luxhomekeke kwizixhobo eziphucukileyo, iitalente ezigqwesileyo kunye neteknoloji eyomeleziweyo ngokuqhubekayo kwintengiso eshushu iSilicon Carbide Wear Resistant Parts Sisic ityhubhu, Kumgangatho ophezulu wegesi welding & nezixhobo zokusika ezibonelelwe ngexesha nangexabiso elifanelekileyo, unokuthembela kwigama eliqinileyo.

Uphuhliso lwethu luxhomekeke kwizixhobo eziphambili, iitalente ezigqwesileyo kunye nemikhosi yetekhnoloji eyomelezwa ngokuqhubekayoChina Refractory Ceramics kunye Kiln Ifenitshala, Sigxile ekuboneleleni ngenkonzo kubaxumi bethu njengento ephambili ekomelezeni ubudlelwane bethu bexesha elide. Ubukho bethu obuqhubekekayo bempahla yodidi oluphezulu ngokudityaniswa nenkonzo yethu ebalaseleyo yokuthengisa kwangaphambili nasemva kokuthengisa kuqinisekisa ukhuphiswano olomeleleyo kwimakethi ekhulayo yehlabathi.

Sinokubonelela ngokuzinzileyo kwaye sithembekileiinqanawa ze-silicon carbide crystal, iipaddles ze-silicon carbide, iityhubhu ze-silicon carbide ezikokushishino lwe-intshi ezi-4 ukuya kwi-intshi ezi-6 zesemiconductor. Ubunyulu bunokufikelela kwi-99.9% ngaphandle kokungcolisa i-wafer.

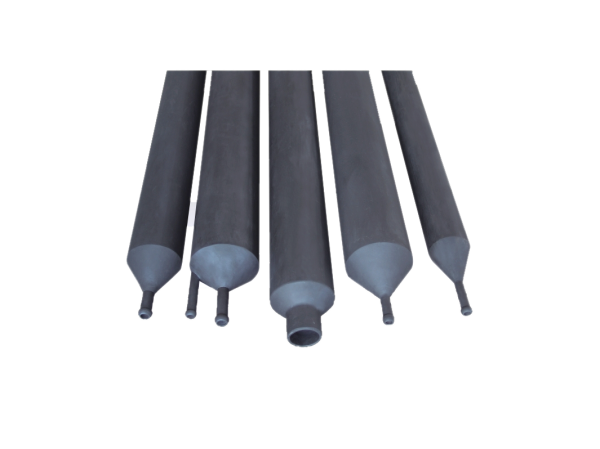

Silicon carbide eziko ityhubhuisetyenziswa ikakhulu kwi: 4-6 intshi yesilicon wafer LTO= silica, SIPOS= oxy-polysilicon, SI3N4= silicon nitride, PSG= phosphosilicon glass, POLY= polysilicon ukukhula kwefilimu. Yigesi ekrwada (okanye i-gasification yomthombo wolwelo) eyenziwa ngamandla ashushu ukuvelisa ifilimu eqinileyo kumphezulu we-substrate. Uxinzelelo oluphantsi lweekhemikhali zokubekelwa komphunga lwenziwa kuxinzelelo oluphantsi, ngenxa yoxinzelelo oluphantsi, umyinge okhululekileyo wendlela yeemolekyuli zegesi mkhulu, ukuze ukufana kwefilimu ekhulileyo kulunge, kwaye i-substrate inokubekwa ngokuthe nkqo kunye nomthamo ukulayishwa kukhulu, ngokukodwa ukulungelelaniswa kweesekethe ezinkulu ezidibeneyo, izixhobo ezicacileyo, i-electronics yamandla, izixhobo ze-optoelectronic kunye ne-fiber optical kunye namanye amashishini okuvelisa izixhobo ezikhethekileyo.

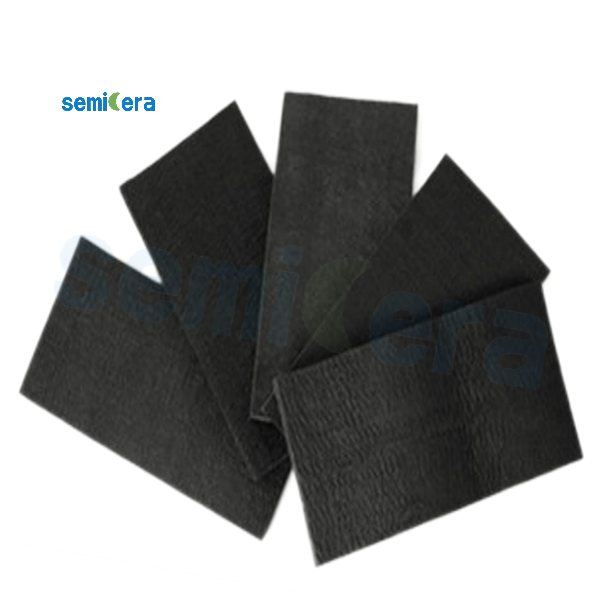

I-Semicera Energy Technology Co., Ltd luphando lobungcali, uphuhliso, ukuveliswa kunye nokuthengiswa kweemveliso ze-silicon carbide ceramic. Ukusukela ekusekweni kwayo ngo-2016, i-Semicera Energy ikwazile ukubumba inkqubo yokubumba i-isostatic, inkqubo yokubumba iwaka, inkqubo yokubumba i-grouting kunye nenkqubo yokubumba i-vacuum extrusion. Inkampani yethu isebenzisa iilayini ezi-6 ze-silicon carbide ceramic sintering sintering, zine-8 CNC, ii-6 ezichanekileyo zoomatshini bokusila, zinokukubonelela ngesilicon carbide ceramic sintered products, kodwa inokubonelela ngesilicon carbide ceramics, alumina ceramics, aluminiyam nitride ceramics, zirconia ceramics processing service. .

Uphuhliso lwethu luxhomekeke kwizixhobo eziphucukileyo, iitalente ezigqwesileyo kunye neteknoloji eyomeleziweyo ngokuqhubekayo kwintengiso eshushu iSilicon Carbide Wear Resistant Parts Sisic ityhubhu, Kumgangatho ophezulu wegesi welding & nezixhobo zokusika ezibonelelwe ngexesha nangexabiso elifanelekileyo, unokuthembela kwigama eliqinileyo.

Intengiso eshushuChina Refractory Ceramics kunye Kiln Ifenitshala, Sigxile ekuboneleleni ngenkonzo kubaxumi bethu njengento ephambili ekomelezeni ubudlelwane bethu bexesha elide. Ubukho bethu obuqhubekekayo bempahla yodidi oluphezulu ngokudityaniswa nenkonzo yethu ebalaseleyo yokuthengisa kwangaphambili nasemva kokuthengisa kuqinisekisa ukhuphiswano olomeleleyo kwimakethi ekhulayo yehlabathi.

-

I-100% ye-Anti-Shock ye-Silicon Carbide cyclon...

-

Isaphulelo esikhulu sePolyacrylonitrile Thermal Insul...

-

2019 Umgangatho ophezulu weSilicon Carbide Liner Sisic T...

-

Umzi-mveliso owenza iWafer Sucker Alumina Semiconduct...

-

Ukufika okutsha kuMzimba oPhantsi ophinde waphinda waphinda wakrola iSilicon...

-

UmGangatho oLungileyo oSetyenzisiweyo weRabha eneMpembelelo ePhakamileyo...