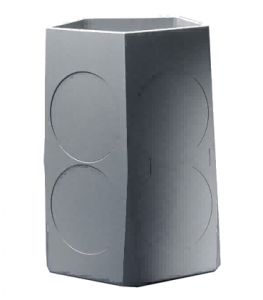

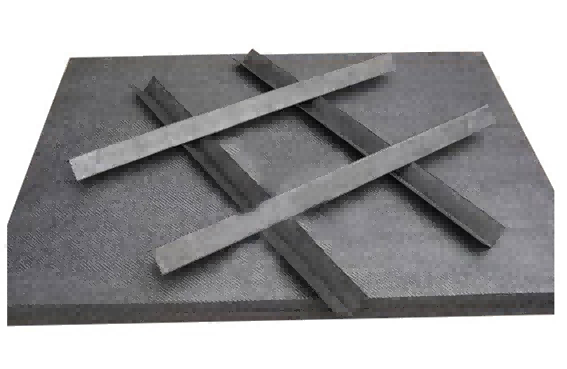

SiC Wafer Boat

Isikhephe seSilicon carbidesisixhobo esithwala umthwalo we-wafers, esetyenziswa kakhulu kwiinkqubo ze-solar kunye ne-semiconductor diffusion. Ineempawu ezinjengokumelana nokunxiba, ukumelana nokugqwala, ukumelana nefuthe lobushushu obuphezulu, ukuchasana ne-plasma bombardment, ubushushu obuphezulu bokuthwala umthamo, ukuhanjiswa kwe-thermal ephezulu, ukukhutshwa kobushushu obuphezulu, kunye nokusetyenziswa kwexesha elide okungekho lula ukugoba kunye nokukhubazeka. Inkampani yethu isebenzisa izinto ezicocekileyo ze-silicon carbide ukuqinisekisa ubomi benkonzo kunye nokubonelela ngoyilo olulungiselelweyo, kubandakanywa. ezahlukeneyo ngokuthe nkqo kunye tyeisikhephe esisicaba.

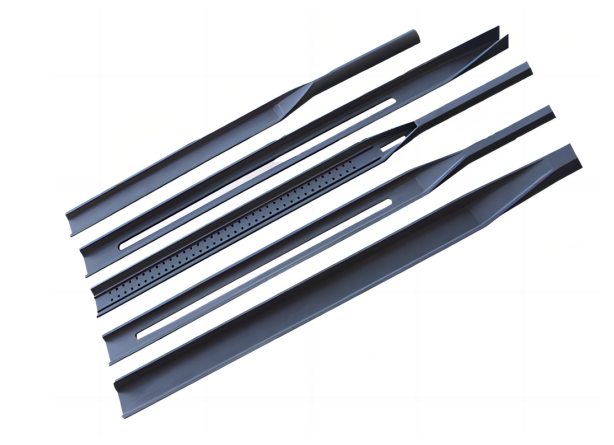

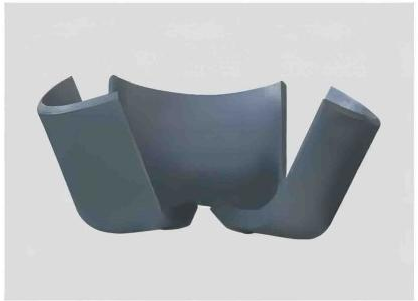

SiC Paddle

Ii-silicon carbide cantilever paddleisetyenziswa ikakhulu ku (ukusasazwa) kokugquma kwee-silicone wafers, ezidlala indima ebalulekileyo ekulayisheni nasekuthuthweni kwee-silicone wafers kubushushu obuphezulu. Lilungu eliphambili leiqhekeza le-semiconductorukulayisha iinkqubo kwaye ineempawu eziphambili zilandelayo:

1. Ayinakuguqulwa kwiindawo eziphakamileyo zeqondo lokushisa kwaye inamandla okulayisha aphezulu kwii-wafers;

2. Iyakwazi ukumelana nokubanda okukhulu kunye nobushushu obukhawulezayo, kwaye inobomi obude benkonzo;

3. I-coefficient yokwandisa i-thermal incinci, yandisa kakhulu umjikelezo wokugcinwa kunye nokucoca, kunye nokunciphisa kakhulu ukungcola.

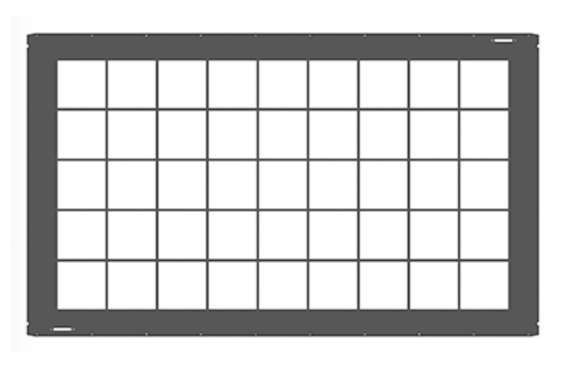

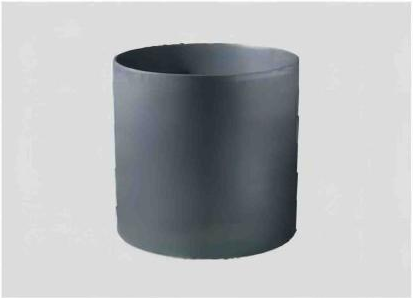

SiC Furnace Tube

Inkqubo ye-silicon carbide tube, eyenziwe nge-SiC ephezulu ecocekileyo ngaphandle kokungcola kwensimbi, ayingcolisi i-wafer, kwaye ifanelekile kwiinkqubo ezifana ne-semiconductor kunye ne-photovoltaic diffusion, annealing and oxidation process.

I-SiC Robot Arm

Ingalo yerobhothi yeSiC, ekwabizwa ngokuba yi-wafer transfer end effector, ingalo yerobhothi esetyenziselwa ukuthutha ii-semiconductor wafers kwaye isetyenziswa ngokubanzi kwi-semiconductor, i-optoelectronic, kunye namashishini amandla elanga. Ukusebenzisa i-silicon carbide ecocekileyo ephezulu, enobulukhuni obuphezulu, ukumelana nokunxiba, ukuxhathisa kwenyikima, ukusetyenziswa kwexesha elide ngaphandle kokuguqulwa, ubomi benkonzo ende, njl.

Igraphite yokukhula kwekristale

I-graphite ene-petal crucible

ityhubhu yesikhokelo segraphite

Umsesane wegraphite

Ikhaka lobushushu legraphite

ityhubhu ye-graphite electrode

Igrafu yokuphambukisa

I-graphite chuck

Zonke iinkqubo ezisetyenziselwa ukukhulisa i-semiconductor crvstals zisebenza kwindawo yobushushu obuphezulu kunye neendawo ezinobungozi. Indawo eshushu yesithando somlilo sekristale idla ngokuba ne-eguinned enokumelana nobushushu kunye nokumelana nokugqwala okuphezulu. izixhobo zegraphite, ezifana nezifudumezi zegraphite, ii-crucibles, cylinders, deflector, chucks, tubes, rings, holders, nuts, njl.

Igraphite yeSemidonductor Epitaxy

Izahlulo zegraphite zeMOCVD

ISemiconductor yeGraphite Fixture

Inkqubo ye-Epitaxial ibhekisela ekukhuleni kwezinto ze-crystal enye kwi-crystal substrate enye kunye nelungiselelo elifanayo le-lattice njenge-substrate. Ifuna iindawo ezininzi zegraphite zokucoceka okuphezulu kunye nesiseko segraphite kunye ne-SIC yokwambathisa. I-graphite ephezulu ecocekileyo esetyenziselwa i-semiconductor epitaxy inoluhlu olubanzi lwezicelo, ezinokufanisa izixhobo ezisetyenziswa ngokuqhelekileyo kwishishini, Ngexesha elifanayo, liphezulu kakhulu. ubunyulu, ukutyabeka okufanayo, ubomi benkonzo obugqwesileyo, kunye nokumelana nemichiza ephezulu kakhulu kunye nokuzinza kwe-thermal.

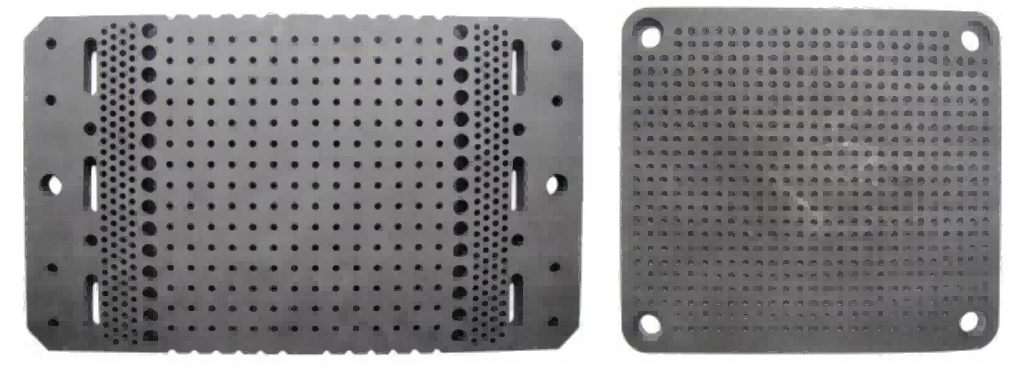

I-Insulation Material kunye nezinye

Izinto zokufakelwa kwe-thermal ezisetyenziswa kwimveliso ye-semiconductor ziyi-graphite evezwa nzima, ivakale ethambileyo, ifoyile yegraphite, imathiriyeli yekhabhoni edityanisiweyo, njl njl. Izinto zethu eziluhlaza zithengwa kwamanye amazwe izinto zegraphite, ezinokuthi zisikwe ngokweenkcukacha zabathengi, kwaye zinokuthengiswa njenge ngokupheleleyo. Izinto zekhabhoni ezihlanganisiweyo zidla ngokusetyenziswa njengomphathi we-solar monocrystal kunye nenkqubo yokuvelisa iiseli ze-polysilicon.