ISilicon Carbide (SiC) Isishwankathelo sePowder

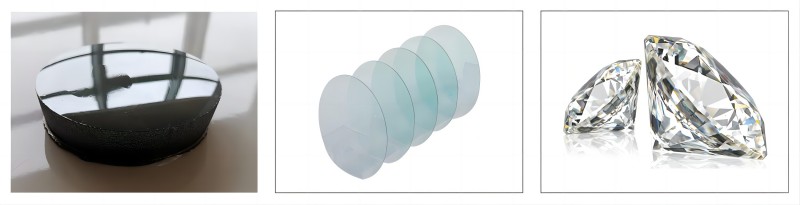

I-Silicon carbide (i-SiC), eyaziwa ngokuba yi-carborundum okanye i-emery, yenye yezona zinto zisetyenziswa kakhulu kunye nezoqoqosho. I-SiC ifumaneka ngeendlela ezimbini: i-silicon carbide emnyama kunye ne-silicon carbide eluhlaza.

Inkqubo yeMveliso

I-SiC iveliswa ngokunyibilikisa isanti ye-quartz, i-petroleum coke, okanye i-coal tar, kunye nee-chips zokhuni kumaqondo aphezulu okushisa kwisithando somlilo. I-silicon carbide eluhlaza yenziwe ngokukodwa ngokunyibilikisa i-silicon dioxide ekumgangatho ophezulu kunye ne-petroleum coke, enetyuwa eyongeziweyo njengesongezo.

Iipropati kunye nezicelo

-Ubunzima:Iwa phakathi kwecorundum nedayimane.

-Amandla oomatshini:Iphakamileyo kune-corundum, i-brittle, kwaye ibukhali.

-Ukuqhuba:Unombane kunye ne-thermal conductivity ethile.

Ngenxa yezi propati, i-SiC ifanelekile kwizicelo ezifuna ukuhlala ixesha elide kunye nokulawulwa kwe-thermal. Isetyenziswa kakhulu kumashishini afana ne-abrasives, refractories, kunye ne-semiconductors.

Iimpawu zeSilicon Carbide

1. Ukwandiswa kweThermal ephantsi:Yehlisa utshintsho kubukhulu ngokuguquguquka kobushushu.

2. High Thermal Conductivity:Ukudlulisa ubushushu ngokufanelekileyo.

3. Ukumelana noxinzelelo lwe-Thermal:Yehlisa ukubakho koxinzelelo lwe-thermal.

4. Okugqwesileyo kweThermal Shock Resistance:Ukumelana nokutshintsha kobushushu obukhawulezayo.

5. Ukuchasa ukuMdla:Yomelela ngokuchasene nomonakalo wekhemikhali.

6. UkuNyamezelwa koBubushushu obugqithisileyo: Isebenza kakuhle kwiindawo ezibandayo kakhulu kunye nezishushu.

7. Ukumelana neCreep yobushushu obuphezulu:Ugcina uzinzo kunye namandla kumaqondo obushushu aphezulu.

I-Semicera inokwenza ngokwezifiso i-4N-6N i-silicon carbide powder ngokweemfuno zakho, wamkelekile ukuba ubuze.

| ISIQULATHO SEKHEMICAL | |

| SiC | 98% imizuzu |

| SiO2 | 1% max |

| H2O3 | 0.5% ubukhulu |

| Fe2O3 | 0.4% ubukhulu |

| FC | 0.4% ubukhulu |

| Izinto zeMagnetic | 0.02% ubukhulu |

| IIPROPATI ZOMZIMBA | |

| Ukuqina kukaMoh | 9.2 |

| Indawo yokunyibilika | 2300℃ |

| Ubushushu bokusebenza | 1900℃ |

| Ubunzima obuthile | 3.2-3.45 g/cm3 |

| Unizi lolwapho kuyiwa khona | 1.2-1.6 g/cm3 |

| Umbala | Mnyama |

| Imodyuli yokuqina | 58-65x106psi |

| I-Coefficient yoKwandiswa kweThermal | 3.9-4.5 x10-6/℃ |

| I-Thermal Conductivity | 71-130 W/mK |

| Ubungakanani benkozo | |

| 0-1mm, 1-3 mm, 3-5mm, 5-8mm, 6/10, 10/18,200-0mesh, 325mesh,320mesh,400mesh,600mesh,800mesh,1000mesh, | |