I-graphite ene-petal crucibleUkukhula kwekristale ye-semiconductor: Yenziwe ngezinto ezisulungekileyo ezisulungekileyo kwaye zenziwe ngetekhnoloji echanekileyo, inokumelana nobushushu obuphezulu, ukumelana nokugqwala, kunye ne-thermal conductivity. Ngethuba lokusetyenziswa kobushushu obuphezulu, i-coefficient yokwandisa i-thermal incinci, kwaye inokumelana okuthile nokuxhatshazwa kokufudumala ngokukhawuleza kunye nokupholisa. Inokumelana ne-corrosion eyomeleleyo kwizisombululo ze-asidi kunye ne-alkaline kunye nokuzinza okuhle kakhulu kweekhemikhali.

Kumgca wemveliso ye-semicera, siyazisaI-Isostatic GraphiteAmacandelo enzelwe ukukhula kwekristale ye-semiconductor.

Kwi-semicera, sibeka phambili umgangatho kunye nokutsha. Iintsimbi zethu zigqunywe ngazoCVD SiC, okwandisa kakhulu ukuqina kunye nobomi babo. Olu tyatyazo lwe-cutting-edge longeza ngakumbi ukuxhathisa kwabo kwimo engqongileyo yeekhemikhali, kubenza ukuba babe lolona khetho lolona khetho lokwenziwa kwesemiconductor.

Ukuhlangabezana neemfuno ezibangwayo zeshishini le-semiconductor yokukhula okuchanekileyo kwekristale, siye sasebenzisa iinkqubo zezinto eziphambili zokuqinisekisa ukubaI-graphite ene-petal crucibleisebenza kakuhle kwiindawo ezahlukeneyo. Le mveliso ayithwalanga kuphela igama lebrendi ye-semicera, kodwa ikwabonakalisa ukuzibophelela kwethu kutshintsho lwetekhnoloji kunye nokugqwesa komgangatho.

I-Graphite ye-petal crucible ye-Graphite ayilungiswanga kuphela ngobuchule, kodwa iphinda ilawule umgangatho ongqongqo kunye nokuvavanya ukuqinisekisa ukuba yonke imveliso ihlangabezana nemigangatho ephezulu. Nokuba kuphando lwebhubhoratri okanye kwizicelo zemizi-mveliso, i-Graphite yethu ye-petal crucible inokwenza ngokuzinzileyo nangokuthembekileyo ukukunceda ufikelele kwinqanaba eliphezulu lokukhula kwekristale ye-semiconductor.

Xa ukhetha i-Graphite ye-petal crucible esuka kwi-semicera, awufumani nje ukusebenza okugqwesileyo, kodwa uthembele kwiteknoloji entsha. Yiba namava ngeemveliso zethu ngoku kwaye ube namava okunokwenzeka okungapheliyo okuziswe ngomgangatho obalaseleyo!

Iimveliso eziphambili ze-semicera ngamasuntswana amahle e-isostatically ecinezelwe igraphite esetyenziswa kwiisemiconductors. Ulwazi olusisiseko lweyona SGL yaseJamani iphuhlileyo kwihlabathi kunye neemveliso zekhabhoni zaseJapan zeToyo zezi zilandelayo:

| Ipharamitha yokusebenza | semicera | SGL R6510 | I-TOYO IG310 |

| Ubuninzi bobuninzi (g/cm3) | 1.91 | 1.83 | 1.85 |

| Amandla okugoba (MPa) | 8-10 | 60 | 49 |

| Amandla acinezelayo (MPa) | 135 | 130 | 103 |

| Ukuqina konxweme (HS) | 70 | 64 | 60 |

| I-Thermal conductivity(W/m·K) | 85 | 105 | 130 |

| I-Coefficient yokwandiswa kwe-thermal(10-6/K) | 5.85 | 4.2 | 5.0 |

| Ukuxhathisa (μΩm) | 11-13 | 13 | 10 |

Inzuzo yokusebenza:

1.Isakhiwo silungile kwaye sixinene, kwaye ukufana kuhle.

I-2.I-coefficient ephantsi yokwandiswa kwe-thermal, ukuxhathisa ukothuka kwe-thermal;

3.Isotropy;

4.Ukuxhathisa iikhemikhali ezinamandla;

5.Good thermal kunye nombane conductivity;

6.It ineempawu ezibalaseleyo machining.

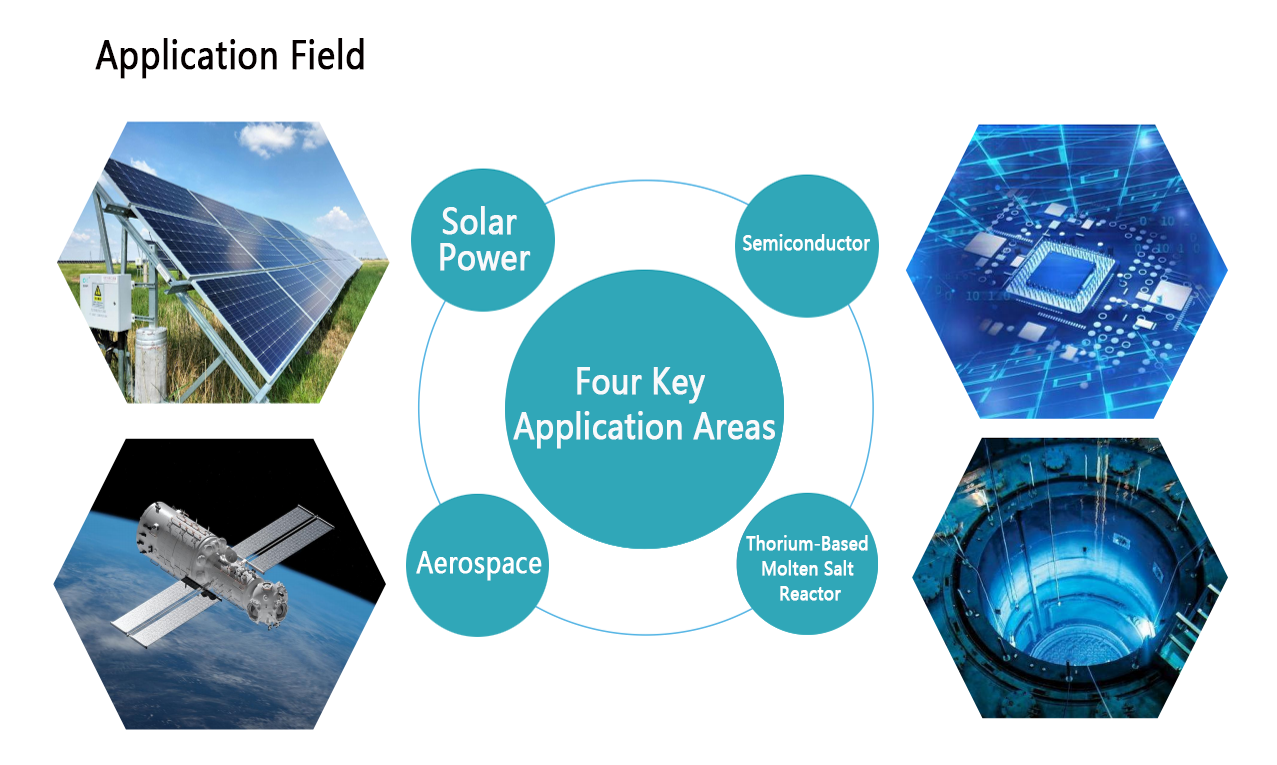

Izinto eziphambili ezisisiseko kushishino lwangoku

1. Ishishini leSemiconductor

2. Ishishini lamandla elanga

3. Ishishini le-Aerospace

4. Ishishini lenyukliya

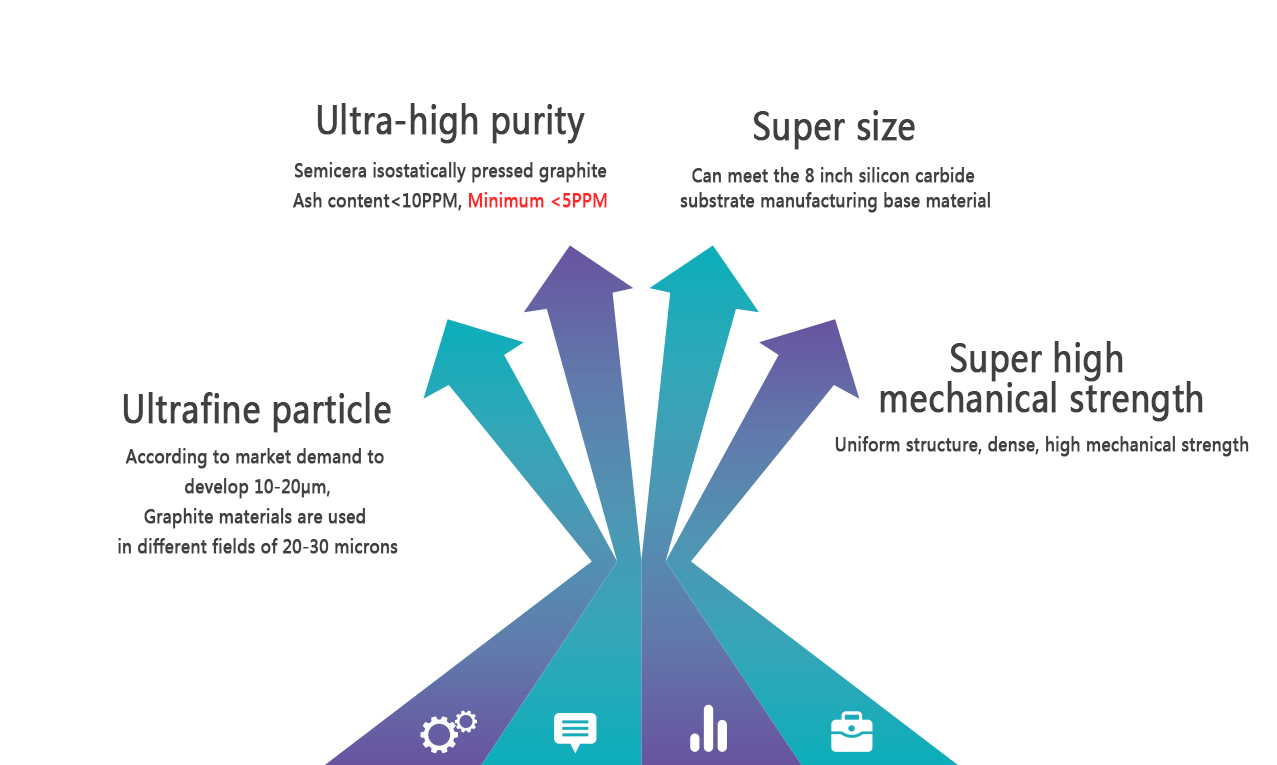

Iprojekthi yegraphite yeSemicera isostatic ecinezelekileyo, ibisenziwa ngobuninzi bemveliso ukufumana uxinaniso oluphezulu, ukucoceka okuphezulu, amandla aphezulu, iimveliso zegraphite ezinobungakanani obukhulu.

-

I-graphite enelobe ezintathu-cauldron egqwesileyo...

-

Izahlulo zeGrafite ezenziwe ngoBunjineli obuchanekileyo yiSemicera...

-

I-Crucible yokutsala i-silicon enye crystal

-

Umgangatho oPhezulu weGraphite yokuFundisa izinto ngeSemic...

-

Izincedisi zeGraphite zentsimi eshushu ye-cr enye...

-

Izisombululo zeGrafite zeSemicera zeSemicond...