Izixhobo zegraphite kwiziko lekristale enye kwishishini le-photovoltaic zidlala indima ebalulekileyo ekwenzeni iiseli zelanga. Zichaphazela ngokuthe ngqo ukuveliswa kwemveliso kunye nomgangatho weeseli zelanga ngokubonelela ngeendawo ezizinzileyo ze-thermal kunye nokuxhasa ukukhula kwe-silicon enye i-crystals. Ke ngoko, uphando kunye nophuhliso kunye nezinto ezintsha ziqhutyelwa ngokuqhubekayo ukuphucula ukusebenza, ukuqina kunye nokulungelelaniswa kwezixhobo zegraphite ukuhlangabezana neemfuno zeshishini le-photovoltaic eliguqukayo.

Intshayelelo:

1. Ukukhethwa kwezinto eziphathekayo: Izixhobo zegraphite zentsimi ye-thermal yesithando somlilo se-crystal enye kwishishini le-photovoltaic ngokuqhelekileyo lisebenzisa izinto ezicocekileyo zegraphite. Ezi zixhobo zegraphite kufuneka zibe nococeko oluphezulu, umxholo wokungcola ophantsi kunye ne-conductivity egqwesileyo ye-thermal ukuqinisekisa ukuzinza kwentsimi ye-thermal kunye nokuqina kwiindawo eziphezulu zokushisa.

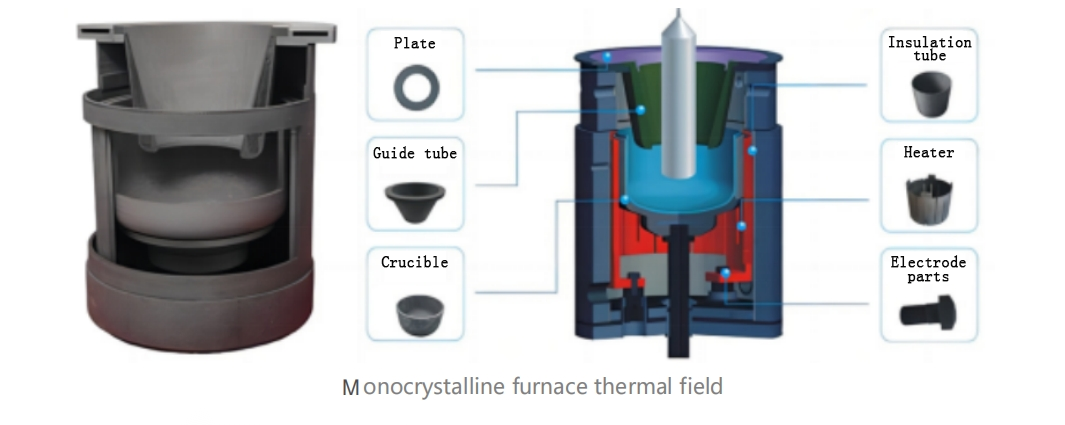

2. Uyilo lwentsimi ye-thermal: Uyilo lwezixhobo zegraphite kwintsimi ye-thermal yesithando somlilo se-crystal enye kufuneka siqwalasele ukufana kunye nokuzinza kwentsimi ye-thermal. Ubume kunye nesakhiwo sezixhobo zegraphite zidlala indima ebalulekileyo ekuqhubeni nasekuhanjisweni kwentsimi ye-thermal ukuze kuqinisekiswe ukuba i-silicon enye i-crystal ifudumala ngokulinganayo kwisithando somlilo kwaye ifumana ukusabalalisa ukushisa okuhambelanayo.

3. I-Thermal conductivity: Izixhobo zegraphite kwintsimi ye-thermal yesithando somlilo esisodwa kwi-photovoltaic industry kufuneka ibe ne-conductivity efanelekileyo ye-thermal ukubonelela ngokuqhuba kakuhle kwe-thermal kunye nokusabalalisa ukushisa okufanayo. Oku kunceda ekuqinisekiseni ukuba i-silicon enye crystal ifudunyezwa ngokulinganayo kuyo yonke inkqubo yokukhula eziko kunye nokunciphisa impembelelo yobushushu bomgangatho wekristale.

4. Ukumelana nokushisa okuphezulu: Ekubeni ubushushu bokukhula kwisithando somlilo se-crystal sihlala siphezulu, izixhobo ze-graphite zentsimi ye-thermal yesithando somlilo se-crystal kwishishini le-photovoltaic kufuneka libe nokumelana nokushisa okuphezulu. Bafanele bakwazi ukugcina ukuzinza kwesakhiwo kunye namandla omatshini kwindawo yokushisa ephezulu ukuze kuqinisekiswe ukusebenza okuzinzileyo kwexesha elide.

5. Ukumelana nokubola: Izixhobo zegraphite zentsimi ye-thermal yesithando somlilo se-crystal enye kwimboni ye-photovoltaic nayo kufuneka ibe nokuchasana kakuhle kwe-corrosion ukuze ihlangabezane neempendulo zemichiza ezinokuthi zenzeke xa zidibana nezinto ze-silicon kunye nezinye iikhemikhali. Oku kunceda ukugcina uzinzo kunye nobomi bezixhobo zegraphite.