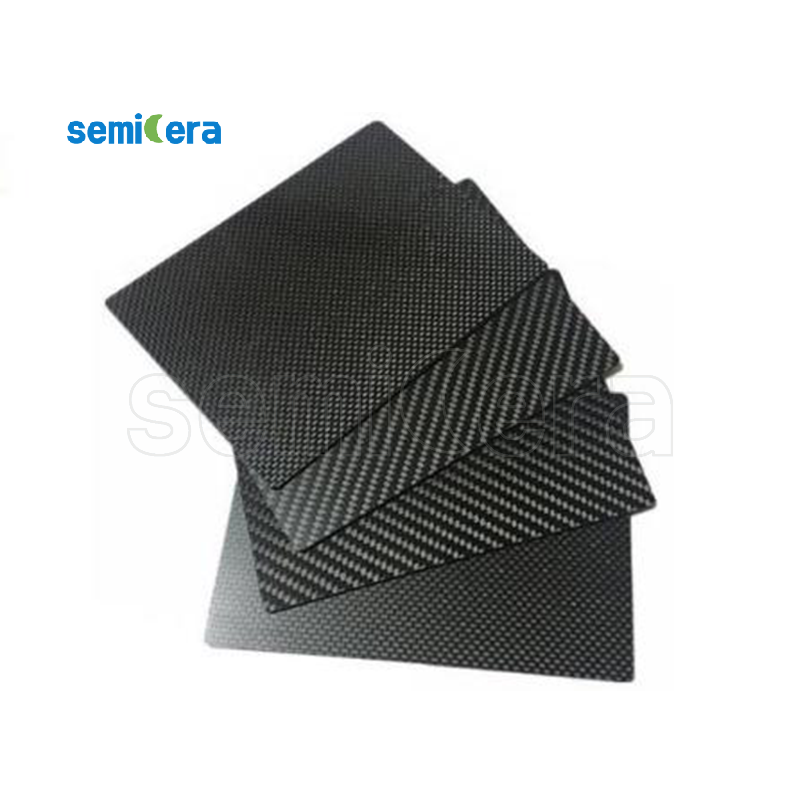

IIiComposites zeCarbon Carbonezibonelelwa yi-Semicera zenzelwe ukuhambisa umsebenzi obalaseleyo kwiindawo ezinobushushu obuphezulu kunye noxinzelelo oluphezulu. Ezi mathiriyeli zihamba phambili, zikwabizwa ngokuba yi-ReinforcedIiComposites zeCarbon-Carbon(RCC), ukunika amandla aphezulu, ukuzinza kwe-thermal, kunye nokuchasana ne-oxidation, okwenza kube lula kuluhlu lwezicelo ezifunwayo, ukusuka kwi-aerospace ukuya kumatshini woshishino.

IiSemicera'sIiComposites zeCarbon Carbonziveliswa kusetyenziswa umgangatho ophezulu we-carbon fiber, ukuhambisa indibaniselwano yeempawu ezilula kunye namandla aphezulu. Oku kubenza bafaneleke ngakumbi usetyenziso olufuna imathiriyeli enokumelana nobushushu obugqithisileyo kunye noxinzelelo, njengakwizithuthi zasemkhathini, iinkqubo zokuqhobosha ezisebenza kakhulu, kunye namacandelo akhethekileyo kwimizi-mveliso.

Ubume be-CC composites buqiniswa ngokusetyenziswa kwekhabhoni ye-carbon fiber-reinforced carbon (CFRC), ukuqinisekisa ukuba izixhobo zigcina ingqibelelo yazo nakwiimeko ezinzima. Ukubunjwa kwezinto zekhabhoni zekhabhoni kunye neengqungquthela ezivela kwi-Semicera nazo zibonelela ngokuqina okuphezulu kunye nokumelana ne-oxidation, ukwandisa ixesha lokuphila kwezinto ezenziwe kuzo.

EziIiComposites zeCarbon Carbonlukhetho oluyimfuneko kumashishini afuna izinto ezilungelelanisa amandla, ukuxhathisa ubushushu, kunye nobunzima, okwenza kube yinto ephezulu kwizicelo ezibalulekileyo. Nokuba ufuna i-CC Composites ye-aerospace, i-automotive, okanye ukusetyenziswa kwemizi-mveliso, iimveliso ze-Semicera ziqinisekisa ukusebenza kwinqanaba eliphezulu.

| Idatha yobuGcisa yeCarbon / Carbon Composite |

| ||

| Isalathiso | Iyunithi | Ixabiso |

|

| Unizi lolwapho kuyiwa khona | g/cm3 | 1.40~1.50 |

|

| Umxholo wekhabhoni | % | ≥98.5~99.9 |

|

| Uthuthu | PPM | ≤65 |

|

| I-Thermal conductivity (1150℃) | W/mk | 10-30 |

|

| Tensile strength | Mpa | 90-130 |

|

| Amandla e-Flexural | Mpa | 100~150 |

|

| Amandla acinezelayo | Mpa | 130-170 |

|

| Amandla okucheba | Mpa | 50~60 |

|

| Amandla e-Interlaminar Shear | Mpa | ≥13 |

|

| Ukumelana nombane | Ω.mm2/m | 30-43 |

|

| I-Coefficient yoKwandiswa kweThermal | 106/K | 0.3~1.2 |

|

| Ukuqhuba Ubushushu | ℃ | ≥2400℃ |

|

| Umgangatho womkhosi, ukubekwa kwesithando somlilo sekhemikhali esipheleleyo somphunga, ukufakwa ngaphandle kweToray carbon fiber T700 yokunitha inaliti ye-3D yangaphambili. |

| ||

Imixube yeKhabhoni yeCarbon:

Iicomposites zeCarbon carbon (i-Carbon-fiber-reinforced carbon composite) (CFC) luhlobo lwemathiriyeli eyenziwe ngamandla aphezulu ekhabhon fiber kunye ne-carbon matrix emva kokulungiswa kophuculo lwegraphitization.

Ingasetyenziswa ngokubanzi kwindawo yokushisa ephezulu yesakhiwo esahlukileyo, i-heater kunye nesitya. Xa kuthelekiswa nezinto zobunjineli bemveli, i-carbon carbon composite inezi nzuzo zilandelayo:

1) Amandla aphezulu

2) Ubushushu obuphezulu ukuya kuthi ga kwi-2000℃

I-3) Ukuxhatshazwa kwe-thermal shock

4) I-coefficient ephantsi yokwandiswa kwe-thermal

5) Umthamo omncinci we-thermal

I-6) Ukuchasana nokugqwesa okugqwesileyo kunye nokumelana nemitha

Isicelo:

1. I-Aerospace. Ngenxa yezinto ezidibeneyo zinokuzinza okuhle kwe-thermal, amandla athile aphezulu kunye nokuqina. Ingasetyenziselwa ukwenziwa kweebhuleki zenqwelomoya, iphiko kunye nefuselage, i-antenna yesathelayithi kunye nesakhiwo senkxaso, iphiko lelanga kunye neqokobhe, iqokobhe elikhulu le-rocket, iqokobhe le-injini, njl.

2. Ushishino lweemoto.

3. Icandelo lezonyango.

4. Ukushisa-ukufudumala

5. Iyunithi yokufudumeza

6. I-Ray-insulation

-

I-C / C idibanisa kunye ne-conductivity ephezulu ye-thermal

-

Iimveliso zeCarbon fibre C/C imathiriyeli edibeneyo

-

I-C/C Composite (CFC) Isakhelo seMathiriyeli

-

Isiko lobushushu obuphezulu obuxhathisa iC/C Composite...

-

Amandla aphezulu kunye nobushushu obuphezulu be-thermal fiel...

-

Idityanisiwe yeC/C eyomeleziweyo