I-Silicon carbide (SiC) imathiriyeli yekristale enye inobubanzi bebhendi enkulu (~Si 3 amaxesha), i-thermal conductivity ephezulu (~Si 3.3 amaxesha okanye GaAs 10 amaxesha), izinga eliphezulu lokufuduka kwe-electron (~Si 2.5 amaxesha), ukuphuka okuphezulu kombane intsimi (~ Si 10 amaxesha okanye GaAs 5 amaxesha) kunye nezinye iimpawu ezibalaseleyo.

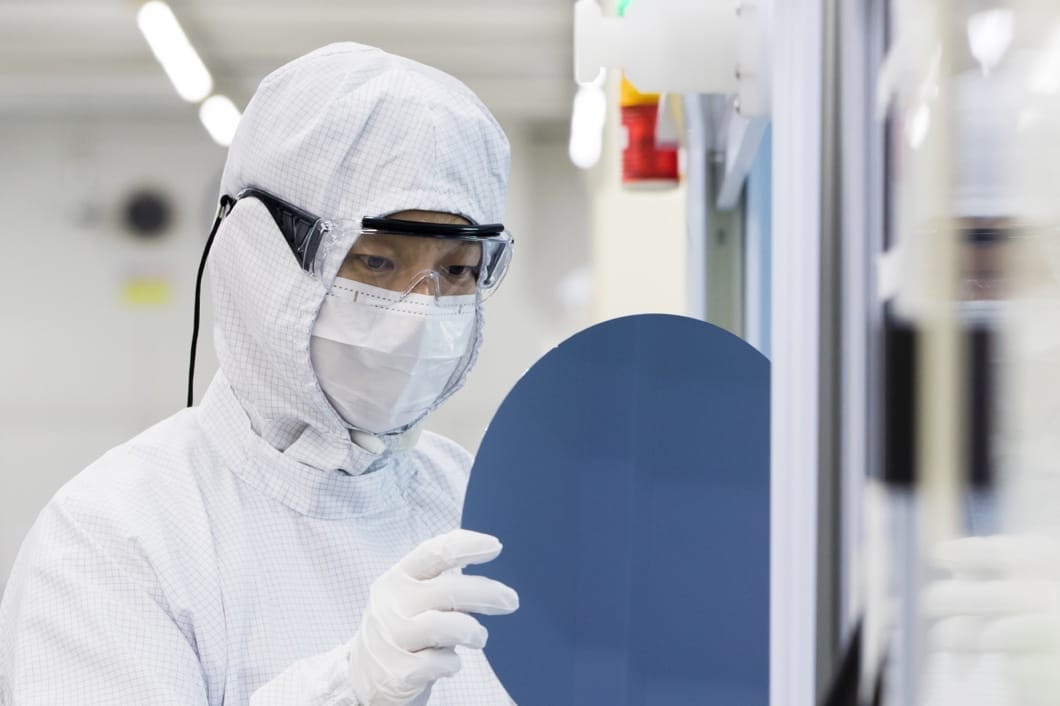

Amandla e-Semicera anokubonelela abathengi ngekhwalithi ephezulu ye-Conductive (i-Conductive), i-Semi-insulating (i-Semi-insulating), i-HPSI (i-High Purity semi-insulating) i-silicon carbide substrate; Ukongeza, sinokubonelela abathengi nge-homogeneous kunye ne-heterogeneous silicon carbide epitaxial sheets; Sinokwenza ngokwezifiso iphepha le-epitaxial ngokweemfuno ezithile zabathengi, kwaye akukho xabiso lincinci lomyalelo.

| Izinto | Imveliso | Uphando | Dummy |

| Iiparamitha zeCrystal | |||

| Iipolytype | 4H | ||

| Imposiso yokujonga umphezulu | <11-20>4±0.15° | ||

| Iiparamitha zoMbane | |||

| I-Dopant | n-uhlobo lweNitrojeni | ||

| Ukuxhathisa | 0.015-0.025ohm · cm | ||

| Iiparamitha zoomatshini | |||

| Ububanzi | 99.5 - 100mm | ||

| Ukutyeba | 350±25 μm | ||

| Ukuqhelaniswa neflethi ephambili | [1-100] ± 5 ° | ||

| Ubude beflethi bokuqala | 32.5±1.5mm | ||

| Indawo ethe tyaba yesibini | 90° CW ukusuka kwiflethi yokuqala ±5°. ubuso besilicon phezulu | ||

| Ubude beflethi yesibini | 18±1.5mm | ||

| TTV | ≤5 μm | ≤10 μm | ≤20 μm |

| LTV | ≤2 μm(5mm*5mm) | ≤5 μm(5mm*5mm) | NA |

| Ukuqubuda | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| I-Wap | ≤20 μm | ≤45 μm | ≤50 μm |

| Ngaphambili(Si-face) uburhabaxa(AFM) | Ra≤0.2nm (5μm*5μm) | ||

| Ulwakhiwo | |||

| Ukuxinana kweMibhobho | ≤1 nge-cm2 | ≤5 i/cm2 | ≤10 i/cm2 |

| Ukungcola kwesinyithi | ≤5E10athom/cm2 | NA | |

| I-BPD | ≤1500 i-ea/cm2 | ≤3000 i/cm2 | NA |

| TSD | ≤500 i/cm2 | ≤1000 nge-cm2 | NA |

| Umgangatho wangaphambili | |||

| Ngaphambili | Si | ||

| Ukugqitywa komphezulu | Si-ubuso CMP | ||

| Amacandelo | ≤60ea/wafer (ubukhulu≥0.3μm) | NA | |

| Imikrwelo | ≤2ea/mm. Ubude obongezelekayo ≤Ububanzi | Ubude obongezelekayo≤2*Ububanzi | NA |

| Amaxolo e-orenji/imingxuma/amabala/imivimbo/ iintanda/ungcoliseko | Akukho nanye | NA | |

| Iitshiphusi ze-Edge/i-idents/fracture/hex plates | Akukho nanye | NA | |

| Iindawo zePolytype | Akukho nanye | Indawo eyongezelekayo≤20% | Indawo eyongezelekayo≤30% |

| Ukumakishwa kwelaser yangaphambili | Akukho nanye | ||

| Umgangatho wasemva | |||

| Emva kokugqiba | C-ubuso CMP | ||

| Imikrwelo | ≤5ea/mm,Ubude obongezelekayo≤2*Ububanzi | NA | |

| Iziphene zangasemva (iitshiphusi zomphetho/iindindi) | Akukho nanye | ||

| Umqolo uburhabaxa | Ra≤0.2nm (5μm*5μm) | ||

| Ukumakishwa kwelaser yangasemva | 1 mm (ukusuka kumphetho ophezulu) | ||

| Edge | |||

| Edge | Chamfer | ||

| Ukupakishwa | |||

| Ukupakishwa | Ibhegi yangaphakathi izaliswe yinitrogen kwaye ibhegi yangaphandle iyatshintshwa. Multi-wafer cassette, epi-ready. | ||

| *Amanqaku: "NA" ithetha ukuba akukho sicelo Izinto ezingakhankanywanga zinokubhekisa kwi-SEMI-STD. | |||

-

Izinto eziRefractory ezithengiswa kakhulu-ubushushu obuphezulu...

-

Umgangatho olungileyo weWafer Sucker Alumina Semiconductor...

-

Isaphulelo esikhulu seMveliso eNtsha yeCeramic Beam Silico...

-

Imveliso eNtsha yaseTshayina yeSilicon Carbide Radiation Sis...

-

2019 Umgangatho ophezulu weSic Oxide Silicon Carbide Cer...

-

OEM / ODM Factory Silicon Carbide / Sic Mechanical ...