I-Silicon carbide (SiC) imathiriyeli yekristale enye inobubanzi bebhendi enkulu (~Si 3 amaxesha), i-thermal conductivity ephezulu (~Si 3.3 amaxesha okanye GaAs 10 amaxesha), izinga eliphezulu lokufuduka kwe-electron (~Si 2.5 amaxesha), ukuphuka okuphezulu kombane intsimi (~ Si 10 amaxesha okanye GaAs 5 amaxesha) kunye nezinye iimpawu ezibalaseleyo.

Isizukulwana sesithathu semiconductor izixhobo ikakhulu ziquka SiC, GaN, idayimane, njl., kuba umsantsa band yayo ububanzi (Umzekelo) mkhulu okanye ilingana 2.3 electron volts (eV), eyaziwa ngokuba band gap semiconductor ebanzi imathiriyeli. Xa kuthelekiswa nezixhobo ze-semiconductor zesizukulwana sokuqala kunye nesesibini, izixhobo ze-semiconductor zesizukulwana sesithathu zineengenelo ze-thermal conductivity ephezulu, i-high breakdown ibala lombane, izinga eliphezulu lokufuduka kwe-electron kunye namandla aphezulu okubambisana, anokuthi ahlangabezane neemfuno ezintsha zeteknoloji ye-elektroniki yanamhlanje ephezulu. ubushushu, amandla aphezulu, uxinzelelo oluphezulu, amaza omoya aphezulu kunye nokumelana nemitha kunye nezinye iimeko ezinzima. Inamathemba abalulekileyo okusebenza kwiinkalo zokhuselo lwelizwe, inqwelomoya, i-aerospace, ukuhlola i-oyile, ukugcinwa kwamehlo, njl., kwaye inokunciphisa ukulahlekelwa kwamandla ngaphezu kwe-50% kumashishini amaninzi anobuchule afana nonxibelelwano lwe-broadband, amandla elanga, ukuveliswa kweemoto, ukukhanyisa kwe-semiconductor, kunye negridi ehlakaniphile, kwaye inokunciphisa umthamo wesixhobo ngaphezu kwe-75%, into ebalulekileyo ebalulekileyo kuphuhliso lwenzululwazi yoluntu kunye nobuchwepheshe.

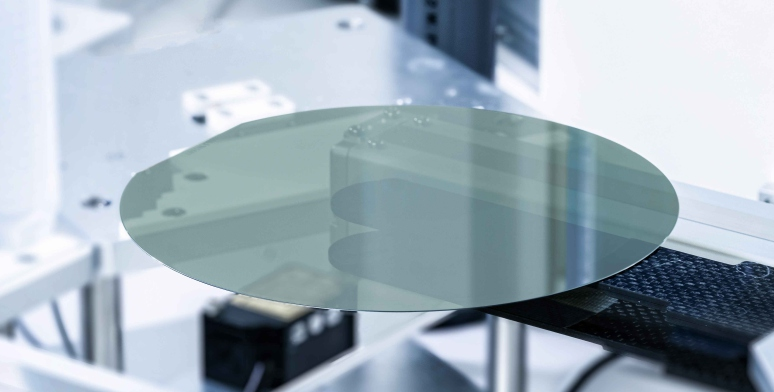

Amandla e-Semicera anokubonelela abathengi ngekhwalithi ephezulu ye-Conductive (i-Conductive), i-Semi-insulating (i-Semi-insulating), i-HPSI (i-High Purity semi-insulating) i-silicon carbide substrate; Ukongeza, sinokubonelela abathengi nge-homogeneous kunye ne-heterogeneous silicon carbide epitaxial sheets; Sinokwenza ngokwezifiso iphepha le-epitaxial ngokweemfuno ezithile zabathengi, kwaye akukho xabiso lincinci lomyalelo.

IINGCACISO ZOKUPHAZAMISEKA

*n-Pm=n-type Pm-Grade,n-Ps=n-type Ps-Grade,Sl=Semi-lnsulation

| Into | 8-intshi | 6-Intshi | 4-intshi | ||

| nP | n-Pm | n-Nd | SI | SI | |

| TTV(GBIR) | ≤6um | ≤6um | |||

| I-Bow(GF3YFCD)-Ixabiso elipheleleyo | ≤15μm | ≤15μm | ≤25μm | ≤15μm | |

| Warp(GF3YFER) | ≤25μm | ≤25μm | ≤40μm | ≤25μm | |

| I-LTV(SBIR)-10mmx10mm | <2μm | ||||

| Wafer Edge | Beveling | ||||

UBUPHAKAMBE GQIBELA

*n-Pm=n-type Pm-Grade,n-Ps=n-type Ps-Grade,Sl=Semi-Insulating

| Into | 8-intshi | 6-Intshi | 4-intshi | ||

| nP | n-Pm | n-Nd | SI | SI | |

| Umphezulu Gqiba | Icala eliphindwe kabini le-Optical Polish, iSi- Face CMP | ||||

| Ubunzima boMphezulu | (10um x 10um) Si-FaceRa≤0.2nm I-C-Face Ra≤ 0.5nm | (5umx5um) Si-Face Ra≤0.2nm I-C-Face Ra≤0.5nm | |||

| IiChips zoMda | Akukho okuvunyelweyo (ubude nobubanzi≥0.5mm) | ||||

| Iindenti | Akukho Ivumelekileyo | ||||

| Imikrwelo(Si-Face) | Ubuninzi.≤5,Yongezeleka Ubude≤0.5×i-wafer diameter | Ubuninzi.≤5,Yongezeleka Ubude≤0.5×i-wafer diameter | Ubuninzi.≤5,Yongezeleka Ubude≤0.5×i-wafer diameter | ||

| Iintanda | Akukho Ivumelekileyo | ||||

| Ukungabandakanywa kuMda | 3mm | ||||