I-Silicon carbide luhlobo olutsha lweekeramics ezinexabiso eliphezulu lokusebenza kunye neempawu ezintle zezinto eziphathekayo.Ngenxa yeempawu ezinje ngokuqina okuphezulu kunye nokuqina, ukumelana nobushushu obuphezulu, ukuguquguquka okukhulu kwe-thermal kunye nokuxhathisa ukubola kweekhemikhali, iSilicon Carbide inokumelana nayo yonke imichiza ephakathi.Ke ngoko, i-SiC isetyenziswa kakhulu kwimigodi yeoli, kwimichiza, koomatshini nakwindawo yomoya, nkqu amandla enyukliya kunye nomkhosi banemfuno zabo ezikhethekileyo kwi-SIC.Esinye isicelo esiqhelekileyo esinokusinika amakhonkco okutywina epompo, i-valve kunye nezixhobo zokukhusela njl.

Siyakwazi ukuyila kunye nokwenza ngokwemilinganiselo yakho ethile ngomgangatho olungileyo kunye nexesha lokuhambisa elifanelekileyo.

I-non-pressure sintered silicon carbide roller, i-atmospheric pressure sintered silicon carbide iimveliso zeceramic, ukusetyenziswa kobunyulu obuphezulu be-silicon carbide powder, efakwe kwi-2450℃ ubushushu obuphezulu, umxholo we-silicon carbide ongaphezulu kwe-99.1%, ubuninzi bemveliso ≥3.10g/ cm3, akukho ukungcola kwesinyithi njengesilicon yesinyithi.

► Umxholo weSilicon carbide --≥99%;

► Ukumelana nokushisa okuphezulu - ukusetyenziswa okuqhelekileyo kwi-1800 ℃;

► High thermal conductivity - xa kuthelekiswa ne-thermal conductivity yezinto zegraphite;

► Ubulukhuni obuphezulu - ukuqina okwesibini kuphela kwidayimane, i-cubic boron nitride;

► Ukuxhatshazwa kwe-Corrosion - i-asidi eyomeleleyo kunye ne-alkali ayinayo nayiphi na i-corrosion, ukumelana ne-corrosion kungcono kune-tungsten carbide kunye ne-alumina;

► Ubunzima bokukhanya - ubuninzi be-3.10g / cm3, kufuphi ne-aluminium;

► Akukho deformation - i-coefficient encinci kakhulu yokwandiswa kwe-thermal;

► Ukuxhatshazwa kwe-thermal shock - izinto eziphathekayo zinokumelana nokutshintsha kweqondo lokushisa ngokukhawuleza, ukuxhathisa ukutshatyalaliswa kwe-thermal, ukuchasana nokubanda kunye nokushisa, ukusebenza okuzinzile.

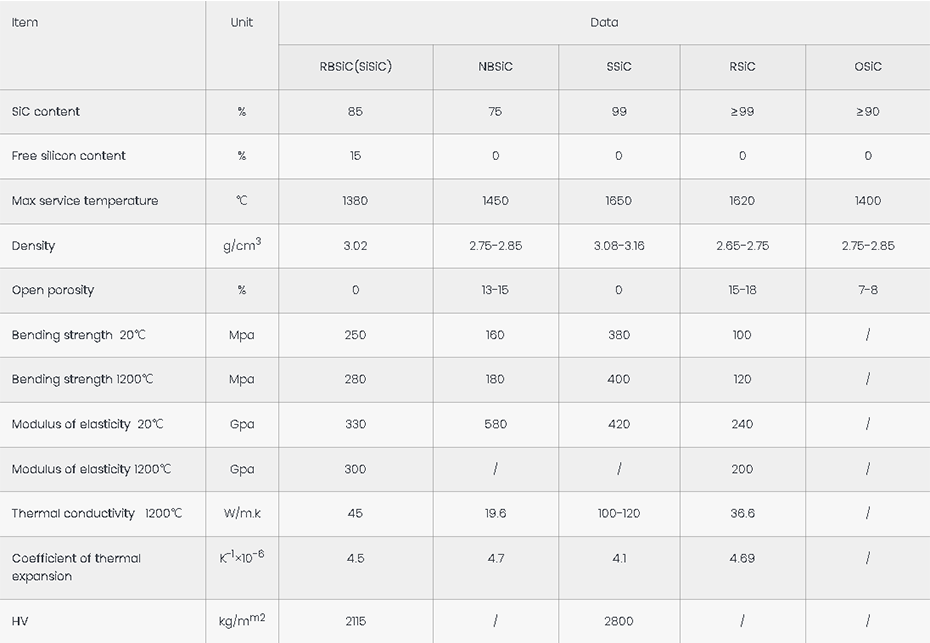

Iiparamitha zobuGcisa:

-

I-silicon carbide igqunywe ngamacala alishumi kwi-cylindrical...

-

Ubushushu obuphezulu kunye neengxenye zequartz ezicocekileyo

-

Ubulukhuni obuphezulu besiko nxiba imoto yesilicon echanekileyo...

-

Umsesane wokutywina we-alumina semiconductor ceramic

-

SiC Bonded Si3N4 Refractory Brick

-

I-Reaction sintered silicon carbide rolls