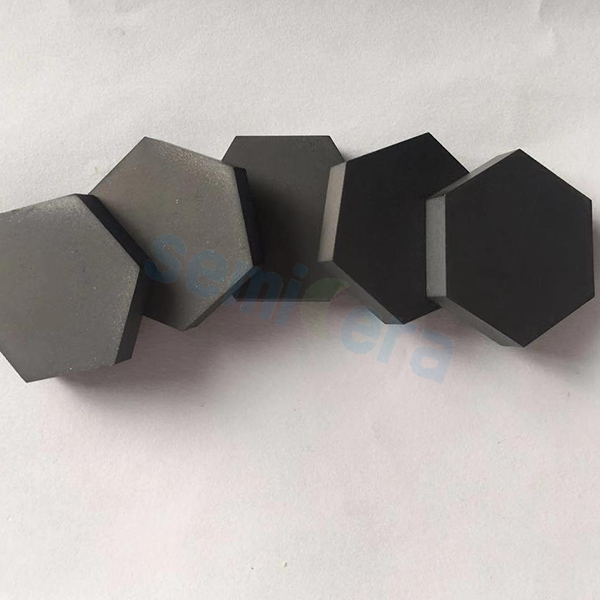

I-Silicon nitride yi-ceramic engwevu enokuqina okuphezulu kokuqhekeka, ukuxhathisa ukothuka kobushushu, kunye neempawu ezingenakungeneka kwiintsimbi ezinyibilikisiweyo.

Usebenzisa ezi mpawu, isetyenziswa kumalungu enjini yokutsha yangaphakathi anje ngeendawo zenjini yemoto, imilomo yemibhobho yomatshini wokuwelda, njl. njl., ngakumbi iindawo ezifuna ukusetyenziswa kwiindawo ezirhabaxa ezinje ngokufudumeza.

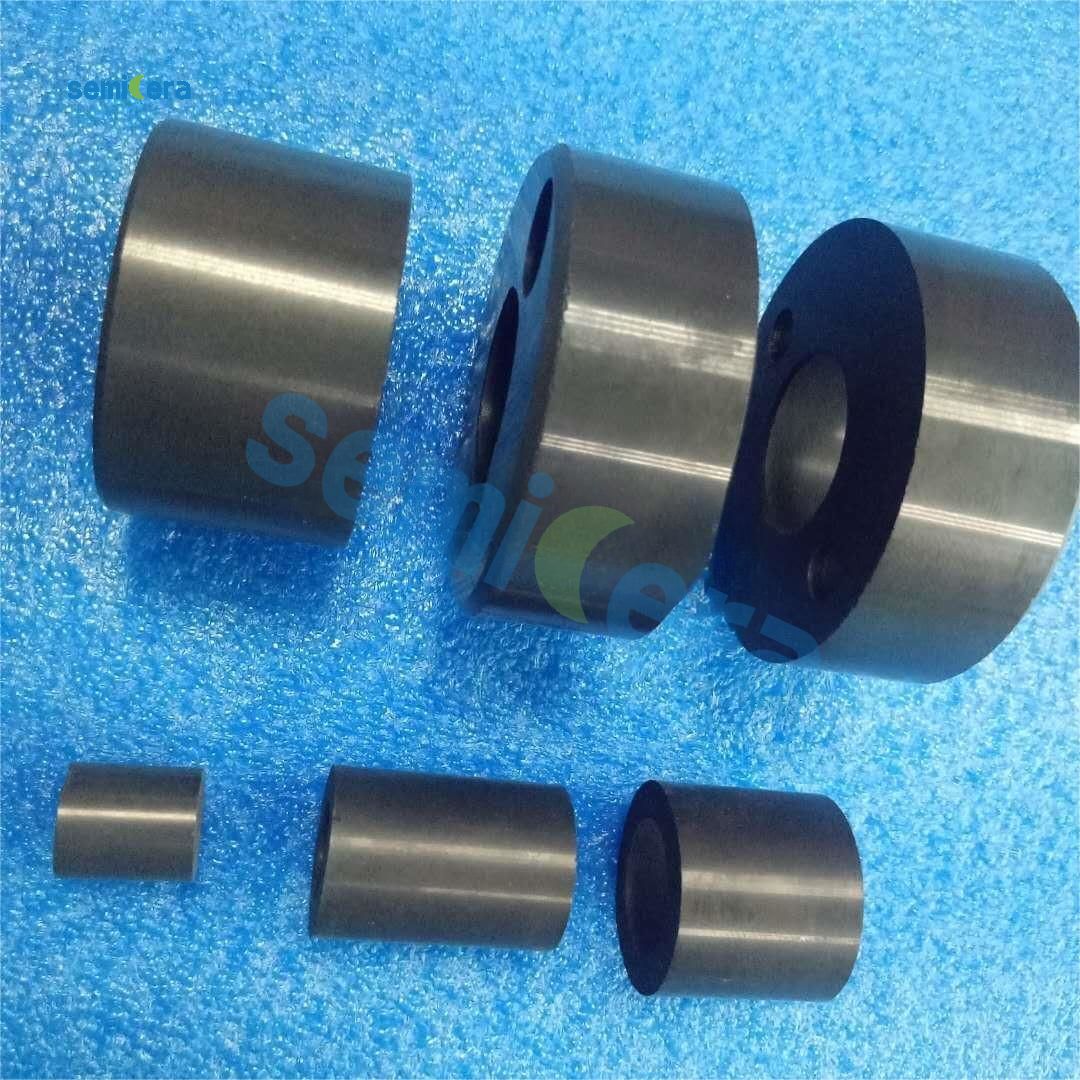

Ngokumelana kwayo okuphezulu kunye namandla aphezulu omatshini, izicelo zayo ekuthwaleni iinxalenye ze-roller, iibheringi ze-shaft ezijikelezayo kunye nezixhobo zokuvelisa izixhobo ze-semiconductor ezisecaleni zihlala zisanda.

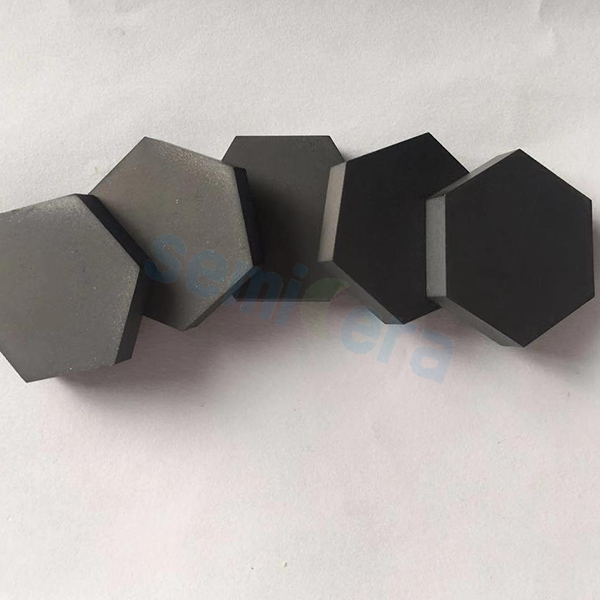

Iipropati ze-silicon nitride ceramics

I-1, inamandla aphezulu kuluhlu olukhulu lobushushu;

2, ukomelela okuphezulu kokuqhekeka;

3, ukomelela okuhle kokugoba;

I-4, ukuchasana nokudinwa koomatshini kunye nokuhamba;

5, ukukhanya - ukuxinana okuphantsi;

6, ubunzima obuphezulu kunye nokumelana nokunxiba;

I-7, ukuxhathisa ukothuka kwe-thermal;

8, ukwanda kwe-thermal ephantsi;

9, i-insulator yombane;

I-10, ukuxhathisa okulungileyo kwe-oxidation;

I-11, ukuxhathisa okulungileyo kokubola kweekhemikhali.

I-Silicon nitride ceramics ine-coefficient ephantsi yokwandiswa kwe-thermal kunye ne-conductivity ephezulu ye-thermal, ngoko ke inokumelana nokutshatyalaliswa kobushushu.Isilicon nitride ecinezelekileyo eshushu ayisayi kwaphuka emva kokuba ifudunyezwe ukuya kutsho kwi-1000℃ kwaye ifakwe emanzini abandayo.Kwiqondo lobushushu elingekho phezulu kakhulu, i-silicon nitride inamandla amakhulu kunye nokumelana nempembelelo, kodwa ngaphezulu kwe-1200 ℃ iya konakaliswa ngokukhula kwexesha lokusetyenziswa, ukuze amandla ayo ancitshiswe, athandeke ngakumbi kumonakalo wokudinwa ngaphezulu kwe-1450 ℃, ngoko ke ukusetyenziswa. yeSi3N4 iqondo lobushushu jikelele alidluli kwi-1300℃.

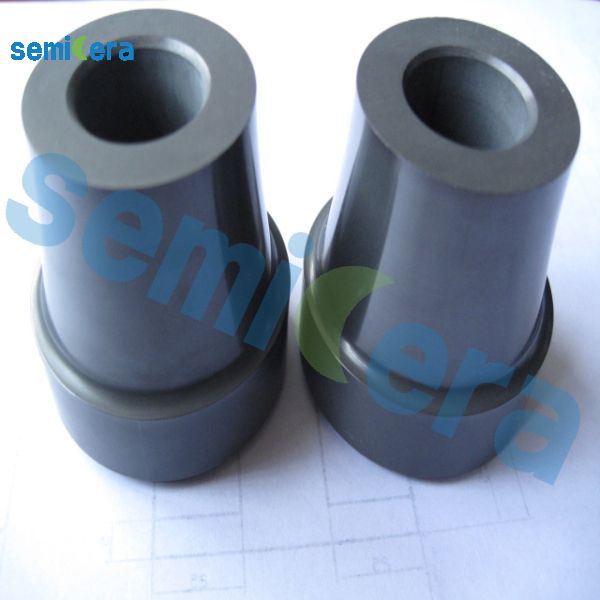

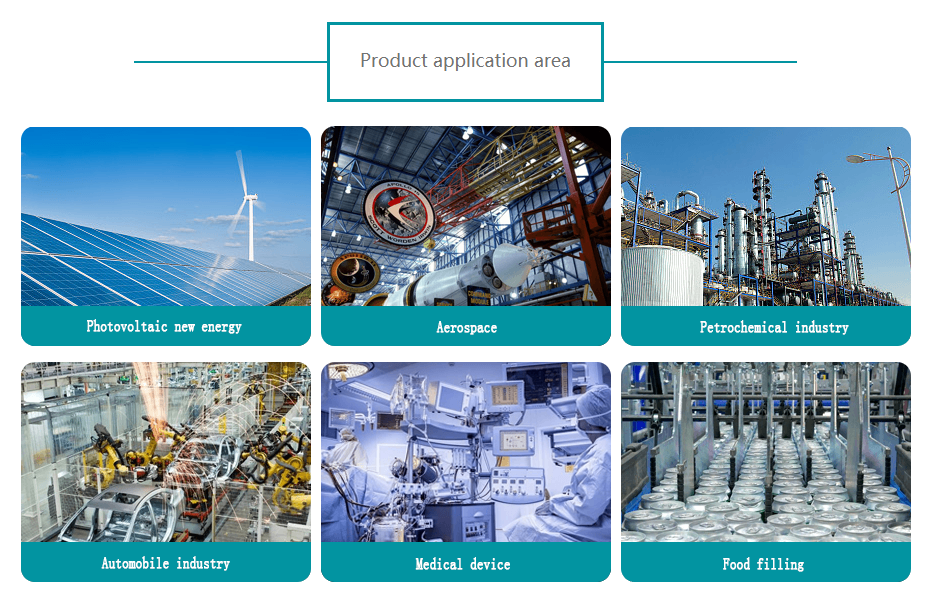

Ke ngoko, i-silicon nitride isetyenziswa ngokubanzi kwi:

1. Ibhola ejikelezayo kunye neebheringi ze-roller;

2. Amacandelo e-injini: ivalve, i-rocker arm pad, indawo yokutywina;

3. Isibiyeli sekhoyili yokufudumeza induction;

4. Iibhleyidi zomoya, iincakuba, iibhakethi;

5. Izinto zokuwelda kunye nebrazing;

6. Indibano yezinto zokufudumeza;

7. Indawo yokuwelda;

8. I-shafts echanekileyo kunye nemikhono kwiindawo eziphezulu zokunxiba;

9. I-Thermocouple sheath kunye ne-tube;

10. Izixhobo zenkqubo ye-semiconductor.

-

Isiqingatha sokuqala-isixhobo se-SiC epitaxial...

-

Iingalo zeceramic ezenziwe ngokwezifiso ze-zirconia zeceramic zesemicond...

-

Isemiconductor i-ceramic insulating ring

-

Custom refractory silicon carbide ipleyiti ceramic

-

Inkqubo eqatywe yeSiC yesiseko segraphite SiC Coated...

-

Ityhubhu ye-silicon carbide esebenzayo ene-goo...