Inkcazo

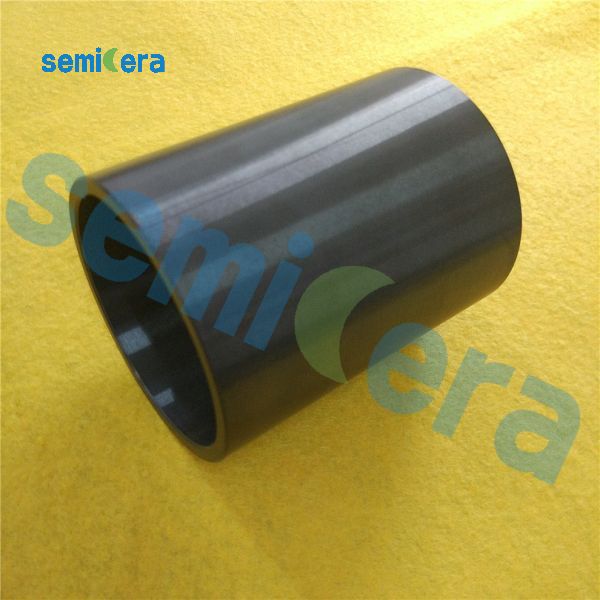

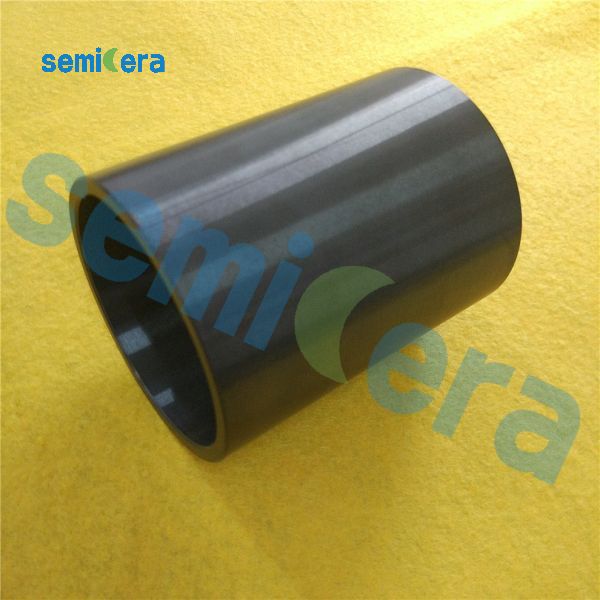

Ukusetyenziswa kweSilicon Carbide igubu lokusila i-ceramic kwinto yokufudumeza

I-silicon carbide i-ceramic grinding barrel iye yaba yinto ekrwada yezinto ze-cathode ze-lithium ibhetri ngenxa yepropathi yayo ebalulekileyo.I-SiC yokufudumeza into ebalulekileyo yimveliso ebalulekileyo ye-SiC kwaye inethemba elibanzi lemarike.

![]()

![]()

I-silicon ye-carbide yokugaya i-barrel inzuzo

(1) Amandla aphezulu oomatshini, njengoko kunjalo

Amandla aphezulu omatshini anokuthintela ngokufanelekileyo ukuguqulwa kwezinto eziphathekayo, okubaluleke kakhulu.I-Silicon carbide inamandla omatshini aphezulu kune-corundum.Umzekelo, amandla acinezelayo e-silicon carbide yi-224MPa, ngelixa i-corundum yi-75.7MPa kuphela.Amandla okugoba e-silicon carbide yi-15.5MPa, kwaye eye-corundum yi-8.72MPa.

(2) Ukumelana nokushisa okuphezulu, i-coefficient encinci yokwandiswa kwe-thermal

I-silicon carbide yenziwa kumaqondo aphezulu.Kwezinye iimeko zokushisa okuphezulu, izinto ezifunekayo ukuba zibe namandla athile okusebenza, kwaye zihlangabezane nokuchaneka kokucubungula, kunye ne-silicon carbide ceramics inokufezekisa la manqaku mabini.Elona qondo liphezulu lokusetyenziswa kwesilicon carbide limalunga ne-800℃, kwaye iqondo lobushushu lentsimbi lingama-250℃ kuphela.Ngokubala ngokurhabaxa, umndilili wokwandiswa kwe-thermal coefficient ye-SIC yi-4.4×10-6/ C kuluhlu lwe-25 ~ 1400℃.I-coefficient yokwandisa i-thermal ye-SIC incinci kakhulu kunezinye iibrasives kunye nezixhobo zokushisa eziphezulu.Ngokomzekelo, i-coefficient yokwandiswa kwe-thermal ye-corundum ingaba phezulu njenge (7 ~ 8) × 10-6 / ℃.

(3) Ukumelana nokubola

I-silicon carbide ngenxa yendawo yokunyibilika (iqondo lobushushu lokubola), inertia yekhemikhali kunye nokuxhathisa ukothuka kwe-thermal kuphezulu, ingasetyenziselwa iintlobo ngeentlobo zeemveliso ze-silicon carbide zeceramic, njengemveliso ye-ceramic yesithando sokugaya izixhobo, ipleyiti yesilingi kunye ne-sagger, i-zinc yokunyibilikisa kwimizi-mveliso ethe nkqo. i-cylinder distillation furnace enezitena ze-silicon carbide, i-aluminium ye-electrolytic cell linening, i-crucible, imathiriyeli encinci yeziko.

Isicelo sokumelana nokubola

I-1, iindawo zokutyibilika (itywina lomatshini, ukuthwala impompo yeekhemikhali, ishaft)

2, izixhobo zokutyumza (umdidiyeli, ilitye lokusila lomoya, ilitye lokusila)

3.Izixhobo zokuvelisa izixhobo zeSemiconductor (iqonga le-XY, i-tray ye-MOCVD, i-ringinging ring, i-wafer chuck)

4. Amacandelo omatshini wokubumba (iinxalenye zomatshini wokubumba ikhamera yekhamera)

5. Iindawo ezikwaziyo ukumelana nobushushu (i-burner burner, iinxalenye zomatshini wokuvavanya ubushushu obuphezulu, i-crucible metal crucible)

.

Ezothutho

FAQ

Umbuzo: Ngaba uyinkampani yokurhweba okanye umenzi?

A: Singaphezu kwe-10 vears mveliso enesatifikethi se-iso9001

Q: Lingakanani ixesha lakho lokuhambisa?

A: Ngokubanzi ziintsuku ezi-3-5 ukuba iimpahla zisesitokhweni, okanye iintsuku eziyi-10-15 ukuba iimpahla azikho kwisitokhwe, ngokobungakanani bakho.

Q: Ndingenza njani Iget isampuli ukujonga umgangatho wakho?

A: Emva kokuqinisekiswa kwexabiso, unokufuna iisampuli ukujonga umgangatho wemveliso yethu.Ukuba ufuna nje isampulu engenanto ukujonga uyilo kunye nomgangatho, siya kukubonelela ngesampulu simahla okoko nje uhlawulela imithwalo ecacileyo.

Q: Ithini imiqathango yakho yentlawulo?

A: Siyayamkela intlawulo yi-Western union, i-Pavpal, i-Alibaba, i-T/TL/Cetc.for bulk order, senza i-30% yediphozithi eseleyo ngaphambi kokuthunyelwa.

ukuba unomnye umbuzo, pls uzive ukhululekile ukuqhagamshelana nathi njengoko kungezantsi.

Kutheni ungakhetha i-Wei Tai?

1) sinesiqinisekiso esaneleyo sesitokhwe.

I-2) ukupakishwa kwengcali kuqinisekisa ukuthembeka kwemveliso.Imveliso iya kuhanjiswa kuwe ngokukhuselekileyo.

3) amajelo angakumbi olungiselelo enza ukuba iimveliso zisiwe kuwe.

-

Silicon carbide wafer sila disk, Ras0.2um

-

Silicon nitride ceramic seal bushing

-

Isiko lokucoceka okuphezulu kwe-silicon carbide yokucola i-lining

-

Ukucoceka okuphezulu kwe-silicon carbide lining, enokwenziwa ngokwezifiso

-

Customizable silicon carbide diffusion paddle

-

Ubunyulu obuphezulu beSiC yesibonisi se-ceramic sinokuba sisiko ...